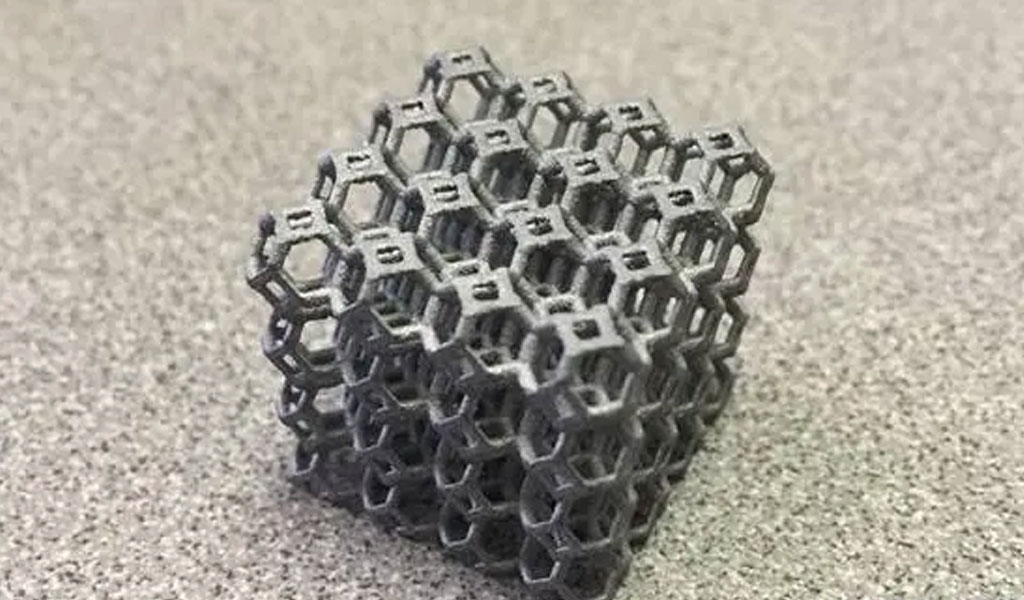

3D printing technology is a rapid additive manufacturing technology that generates three-dimensional solids by adding materials layer by layer. It not only overcomes the loss caused by traditional subtractive manufacturing, but also makes product manufacturing more intelligent, accurate and efficient. Especially when it comes to high-end manufacturing of complex shapes, 3D printing technology shows great advantages. 3D printing technology is a high-tech manufacturing technology with industrial revolution significance, representing a new trend in the development of the world’s manufacturing industry, and has an important leading role in accelerating the development of advanced manufacturing and promoting industrial transformation and upgrading. With the development of high-end manufacturing, China 3D printing manufacturing technology is currently attracting great attention, and together with robotics and artificial intelligence technology, it is known as the key technology to promote the third industrial revolution.

Since 3D printing manufacturing technology has completely changed the molding method and principle of products, which is a subversion of the traditional manufacturing mode, the material bottleneck has become a problem that restricts the development of 3D printing, and it is also the key point and difficulty of 3D printing breakthrough innovation. At present, the commonly used material in 3D printing technology is Plastic material. Using the thermoplastic meltability of Plastic material, in the molten state, it is extruded from the nozzle, and the product is finally formed by solidifying layer by layer. Due to the good thermal fluidity, rapid cooling adhesion and high mechanical strength of Plastic materials, it has been rapidly applied and developed in the field of 3D printing manufacturing. The final development of 3D printing is the application in high-end industrial fields. Resin plastics cannot meet the needs of high-end industrial 3D printing. Therefore, 3D printing materials gradually develop from resin plastics to metal materials.

Metal powder is used as a raw material for 3D printing, and high-power energy beams such as lasers and electron beams are mainly used as heat sources to selectively melt the powder materials. After cooling and crystallization, a stacked layer is formed continuously to form the final product. Due to the high melting temperature of metal powder, it is easy to oxidize, which affects the strength of the product, and the solidification of the material after laser melting will cause the volume of the metal to shrink, resulting in huge thermal stress of the material, which seriously affects the strength of the material. In addition, due to the influence of the particle size and distribution of metal powder, the cooling crystallization process is complex, and the crystallization process is difficult to quantitatively control. Once the crystal coarseness and dendrites appear, the mechanical properties of the material will be reduced after molding, and the final result is the key component. There is no way to get a practical application. Chinese invention patent CN103862040A discloses a magnesium-based metal powder material for 3D printing, which uses magnesium powder wrapped with rosin film as the basic material, nickel powder wrapped with rosin film as the support material, and aluminum powder as the intermediate material , by mixing and stirring. In order to obtain high-strength alloy devices, a variety of metal blending methods are used.

Chinese invention patent CN103801704A discloses a kind of copper powder for 3D printing, adopts argon gas protection furnace to smelt TUO oxygen-free copper to 1250~1400 ° C, and removes the inclusions in molten copper liquid by blowing argon at the bottom of the furnace, so that the copper liquid Fully melted and uniform in temperature. The leaking crucible and the guide nozzle flow through the gas atomization nozzle to form small droplets. The obtained copper powder has a good spherical shape, but a large particle size, so the melting temperature is high when used in 3D printing manufacturing, which is difficult to control.

According to the above, the metal powder currently used in 3D printing manufacturing has problems such as high melting temperature, large particle size, high oxygen content, poor sphericity, poor composition uniformity and poor particle size distribution. Therefore, due to the uneven thickness and uneven melting of metal powder, it will cause volume shrinkage during solidification, resulting in material structural defects and loss of strength.

SUMMARY OF THE INVENTION

Aiming at the defects of the current 3D printing metal powder with coarse particle size, uneven distribution, high oxygen content and high melting temperature, the present invention proposes an aluminum powder for 3D printing. The aluminum powder is based on silica as a carrier. Under vacuum conditions, aluminum is melted at 680 ° C, and then stays in the voids of silica, and is ground into spherical aluminum powder by argon protection, so that the spherical aluminum powder contains oxygen. The rate is reduced to prevent the influence of alumina on the melting of aluminum, and the surface of the aluminum powder is coated and polymerized by the monomer, so that the aluminum powder is used for 3D printing manufacturing. A preparation method for 3D printing aluminum powder is further provided.

An aluminum powder for 3D printing is realized through the following technical solutions: An aluminum powder for 3D printing, characterized in that: using silica as a carrier, the mass ratio of silica and aluminum is 1 : 300-500, the metal aluminum melts and stays in the void of the white carbon black, and the average particle size is 50-100nm and the sphericity is more than 0.75 by grinding and refining to obtain spherical aluminum powder. The surface of the spherical aluminum powder is coated with monomer and Aggregate, which can be used in 3D printing manufacturing.

The pore size of the white carbon black is 100-150 nm.

The monomer is at least one of acrylate, methacrylate and styrene.

A kind of preparation method of the aluminum powder used for 3D printing of the present invention is characterized in that it is carried out in the following manner:

- 1) The metal aluminum with a purity of more than 99.5% is placed in a vacuum furnace, and after melting at 680 ° C, according to The mass ratio of white carbon black and aluminum is 1:300-500. Add white carbon black to the vacuum furnace, maintain the vacuum, and disperse the white carbon black and molten aluminum at a speed of 50-100 rpm for 3-5 minutes, so that the molten aluminum stays in the white

- 2) After cooling the molten aluminum-silica composite obtained in step 1), it is ground under the protection of argon, and the pore size of the silica is 100-150 nm as the aluminum powder granulation. The isolation film is not only easy to grind, pulverize and disperse, but also the obtained aluminum powder has a uniform particle size distribution and low oxygen content;

- 3) 100 parts by weight of the aluminum powder obtained in step 2) and 0.5-1.0 parts by weight of monomers are added Reaction mixer, temperature rises to 80-120 ℃, with the high-speed stirring of 400-900rpm and disperses 15-20 minutes, then adds the initiator of 0.008-0.01 weight part, and described monomer is acrylate, At least one of methacrylate and styrene, the initiator is selected from 2,3-diphenylbutyronitrile, and under the action of the initiator, the monomer is polymerized on the surface of the aluminum powder to form a layer of coating, and the polymerization Coating aluminum powder to obtain an aluminum powder for 3D printing.

The present invention is an aluminum powder for 3D printing. The pore size of white carbon black is 100-150 nm as a separation film for aluminum powder granulation, so that the aluminum 3d printing powder is easy to grind and pulverize, and the obtained aluminum powder is nano-scale with uniform particle size distribution. The sphericity is more than 0.75. In order to make the nano-scale aluminum powder fully dispersed and have adhesiveness, liquid monomer is used to disperse, coat the surface of the aluminum powder and polymerize. The obtained aluminum powder has a low melting temperature and uniform melting. When used for 3D printing manufacturing, the internal structure of the metal is uniform, and the forming accuracy of the product is improved. It can be used to prepare precision metal products of complex components; the surface of the aluminum powder is coated with a thin layer of adhesive by polymerization. , effectively prevent oxidation, so that the aluminum powder used for 3D printing has high fluidity and good thermal bonding formability, the oxygen content is lower than 323ppm, and the polymer coated on the surface of aluminum powder under the condition of 135°C Melt and infiltrate aluminum powder particles for low temperature printing.

- Compared with the prior art, an aluminum powder for 3D printing and a preparation method thereof of the present invention have outstanding features and excellent effects as follows: 1. The aluminum powder for 3D printing of the present invention is made of white carbon. Black is the carrier, the average particle size is 50-100nm, the sphericity is more than 0.75, and the surface of the spherical aluminum powder is coated with monomers and polymerized, which can be used for 3D printing manufacturing.

- The present invention is an aluminum powder for 3D printing, the particle size reaches nano-scale, and the particle size distribution is uniform, so the melting temperature is low and the melting is uniform. When used for 3D printing manufacturing, the internal structure of the metal is uniform, and the forming accuracy of the product is improved. Precision metalwork for making complex components.

- The present invention is an aluminum powder for 3D printing. The surface of the aluminum powder is polymerized and coated with a thin layer of adhesive to effectively prevent oxidation, so that the aluminum powder used for 3D printing has high fluidity and good thermal adhesion. Bonding formability, excellent mechanical properties.

- A preparation method of aluminum powder for 3D printing of the present invention uses the pore diameter of 100-150nm of white carbon black as a separation film for aluminum powder granulation, so that the aluminum powder is easy to grind and pulverize, and the obtained aluminum powder has a uniform particle size distribution , high sphericity, through the coating and polymerization of monomer on the surface of aluminum powder, the coating is complete, and the coating layer is thin, which greatly reduces the influence of the adhesive on the strength of metal products.

Link to this article:A kind of aluminum powder for 3D printing and preparation method thereof

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Silicone And Casting,Thanks!^^